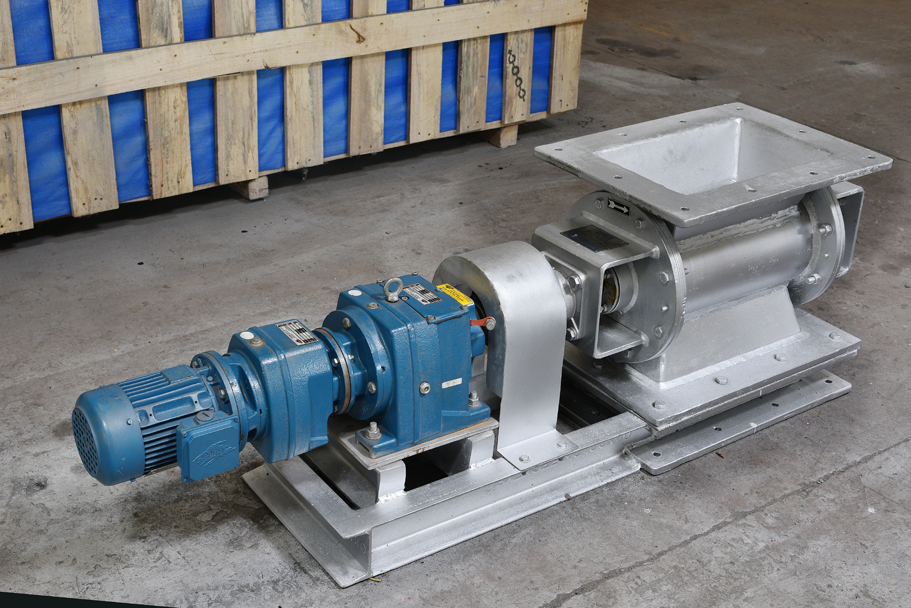

Rotary Air Lock Valves

DEMECH provides a complete range of Rotary Airlock Valves (RAV) suitable for air lock applications ranging from gravity discharge of filters, rotary valves, cyclone dust collectors, and rotary airlock storage devices to precision feeders for dilute phase and continuous dense phase pneumatic conveying systems

RAVs are used in Bulk Handling System for free flowing dry powder, granular, crystal or pellets form of material. It is usually fitted below Chain conveyor / Screw Conveyor / Hopper / Silos / Bag filter / ESP/ Bins etc.

The main function of a RAV is to provide a rated Drop-through discharge, which determines the size and capacity of a RAV Besides this, it also functions as a rotary airlock to seal and prevents possibility of back flow of material in a pressurized system.

The selection of a RAV depends on three main factors i.e. Material density, Capacity desired & flowability of material. Temperature of dust and dust characteristics decide the material of construction of RAV.

RAVs are used for handling various materials including cement, ore, sugar, minerals, grains, plastics, dust, fly ash, flour, gypsum, lime, coffee, cereals, pharmaceuticals etc.